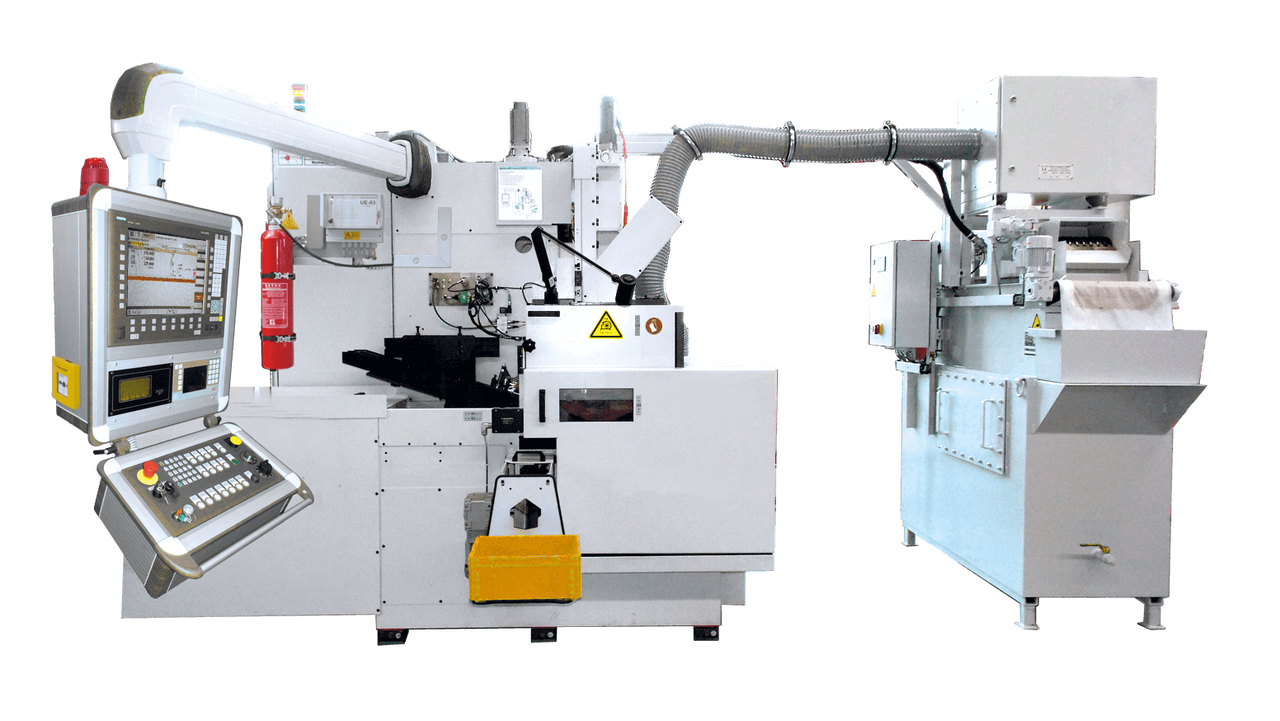

Your individual machine

for vertical centerless grinding

You only have to decide a colour

diagram of machines

| Type of Machine | VSR 425/25 | VSR 523/23 | VSR 525/25 | VSR 530/28 | VSR 640/40 |

|---|

| workpiece data | |||||

| max diameter ** | 60 | 100 | 100 | 100 | 150 |

| max. length ** | 250 | 230 | 250 | 300 | 400 |

| grindwheel data | |||||

| max rotation speed (VS const) [m/s] | 50 | 63 | 63 | 63 | 63 |

| diameter [mm] | 400 | 500 | 500 | 500 | 600 |

| width [mm] | 250 | 230 * | 250 * | 300 * | 400 |

| bore [mm] | 203,2 | 203,2 | 203,2 | 203,2 | 304,8 |

| Regulatingwheel data | |||||

| max rotation speed (VR const) [U/min] | 5-1000 | 5-1000 | 5-1000 | 5-1000 | 5-1000 |

| diameter [mm] | 350 | 350 | 350 | 350 | 350 |

| width [mm] | 250 | 230 | 250 | 280 | 400 |

| bore [mm] | 203,2 | 203,2 | 203,2 | 203,2 | 304,8 |

* = depending on the dressing method

** = special sizes available on request

Highest flexibility through different dressing methods which are optimally adapted to your process

Our special accessories

makes your system even safer

-

filter system

A central system must fulfill many requirements. Our filter systems are designed exactly for the respective grinding application. No matter if emulsion or oil, we offer you a solution adapted to your needs. Compact, space-saving and efficient. -

Exhauster

Harmful substances in indoor air can affect the health of people in the workplace. The use of filter systems to separate oil and emulsion mist helps you to avoid emissions that are hazardous to use. We will find a clean solution together with you. -

Fire extinguishing system

Extinguishing systems provide safety for people and the environment. A single spark can cause devastating damage - so it's better to avoid a fire with a one-time investment. Extinguishing systems protect your employees from burn injuries and your company from long production stoppages. In addition, immediate fire fighting reduces pollutant emissions to a minimum. We are happy to develop a tailor-made protection concept together with our partner. -

UPS (Uninterruptible Power Supply)

A power cut not only costs time, money and nerves. It endangered jobs and infrastructure and can negatively impact a company's image. Many companies rely on the constant flow of electricity. Even a short power cut without effective packup power can have life-threatening consequences. An uninterruptible power supply ensures the operating fundamentals in sensitive areas. -

ESR (extended shutdown and retraction)

emergency retraction in case of power cut. In the event of a power cut, the ESR function ensures that during grinding, the workpiece is withdrawn from the grinding area. Here, the kinetic energy of the rotating grinding spindle is used.

![nomoco - vertical grinding centerless [EN]](/files/default/img/corporate/logo.svg)